In the fast-paced world of modern manufacturing, staying ahead of the competition often hinges on how efficiently an assembly line operates. Enter Simulation services assembly line efficiency—innovative tools that allow businesses to visualize, analyze, and optimize their processes before making costly real-world changes. Simulation services have revolutionized industries by offering insights into production bottlenecks, resource allocation, and process flows. Let’s explore how these services work and their transformative impact on assembly line efficiency.

The Basics of Simulation Services

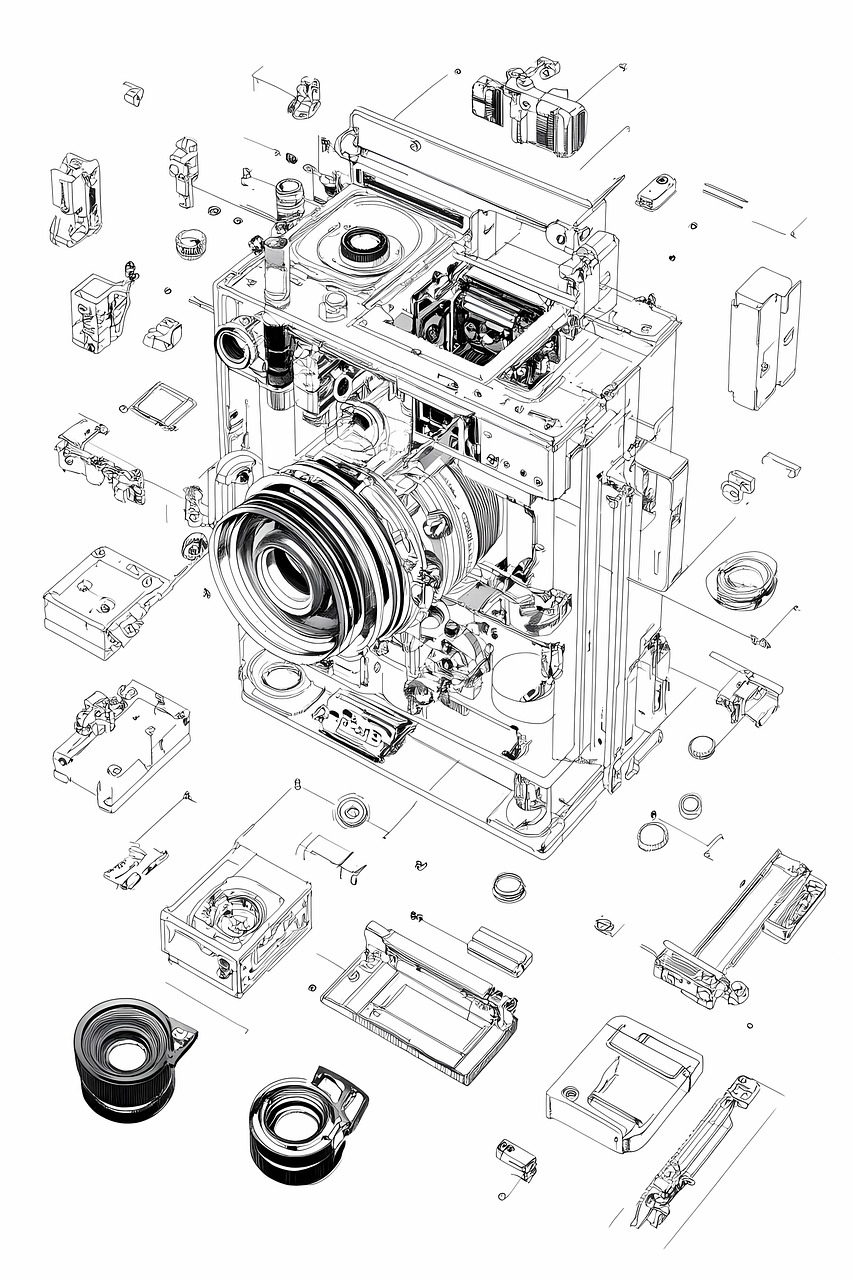

At its core, simulation involves creating a digital twin of an assembly line—a virtual representation that mimics real-world operations. This digital model can then be tested under various conditions to predict outcomes, identify inefficiencies, and evaluate alternative solutions. Popular software platforms for simulation include Siemens Tecnomatix, FlexSim, and AnyLogic, each offering unique capabilities tailored to specific industry needs.

Using simulation services, manufacturers can:

- Test different layouts for an assembly line without physically rearranging equipment.

- Evaluate the impact of new machinery or changes in production schedules.

- Predict potential bottlenecks before they occur.

- Optimize staffing and resource allocation for maximum productivity.

A Personal Anecdote: The Turning Point

To illustrate the power of Simulation services assembly line efficiency, let me share a story from my own experience. Several years ago, I worked with a mid-sized automotive manufacturer that was struggling to meet demand due to inefficiencies in their assembly line. Their operations were plagued by delays caused by mismatched production rates between two critical stations.

We introduced simulation services to help visualize the workflow and pinpoint the issue. After creating a digital twin of the assembly line, the simulation revealed that Station B was consistently operating at 80% capacity while Station A ran at full speed. The imbalance was causing bottlenecks downstream.

With this insight, the company implemented a simple solution: synchronizing the production rates of the two stations. They adjusted the machinery settings and added a buffer storage area to smooth out fluctuations. The results were astonishing. Within weeks, production output increased by 25%, and customer satisfaction improved significantly. This anecdote highlights the tangible benefits of simulation services—by identifying problems virtually, companies can achieve real-world breakthroughs.

Benefits of Simulation services assembly line efficiency

Simulation services bring numerous advantages to assembly lines, including:

- Improved Efficiency: By identifying and addressing bottlenecks, simulation ensures smoother workflows and higher productivity.

- Cost Savings: Testing scenarios virtually reduces the need for costly trial-and-error in real operations.

- Enhanced Flexibility: Manufacturers can quickly adapt to changing demands or implement new technologies with confidence.

- Risk Mitigation: Simulations highlight potential issues before they escalate, minimizing disruptions.

- Data-Driven Decisions: Insights from simulations empower managers to make informed choices backed by accurate predictions.

Importance of simulation services

The importance of simulation services in manufacturing is backed by extensive research and case studies. For more information on the applications and benefits of simulation, check out this resource from the National Institute of Standards and Technology (NIST): https://www.nist.gov/publications/simulation-and-modeling-guide.

The Future of Simulation in Manufacturing

As technology advances, simulation services are becoming even more sophisticated. Integration with artificial intelligence, machine learning, and IoT devices allows for real-time data inputs that refine simulations further. Virtual reality interfaces enable engineers to immerse themselves in the digital twin, fostering a deeper understanding of assembly line dynamics.

Manufacturers that embrace these innovations are well-positioned to lead in a competitive landscape. The ability to predict outcomes, optimize processes, and adapt to challenges will continue to drive growth and success.

Conclusion

Simulation services are more than just tools—they’re transformative agents for manufacturing efficiency. By leveraging digital twins and predictive analytics, businesses can streamline operations, reduce costs, and boost productivity. Whether you’re an industry giant or a budding enterprise, the power of simulation is within reach.

So, are you ready to take your assembly line to the next level? Consider embracing simulation services as your secret weapon for efficiency and innovation. Contact Custom Industrial Solutions LLC today, and let us help you become more efficient in your product line!