Introduction

In the realm of advanced manufacturing, precision and efficiency are indispensable. As industries evolve, adhesive activation has emerged as a pivotal process, ensuring structural integrity and product reliability across a variety of sectors. At Custom Industrial Solutions, our precision presses offer a groundbreaking solution to streamline adhesive activation, improving consistency, throughput, and overall product quality. This blog post delves into the importance of custom precision presses for adhesive activation and how they are reshaping modern manufacturing.

Understanding Adhesive Activation

Adhesive activation is the process of preparing adhesives to bond materials securely and effectively. This can involve applying pressure, heat, or other activation mechanisms to achieve optimal adhesive performance. From automotive to aerospace, adhesives play a critical role in creating durable, lightweight, and versatile products. However, ensuring uniform activation across all components has long posed challenges to manufacturers, leading to the advent of custom precision presses.

The Role of Custom Presses for Adhesive Activation

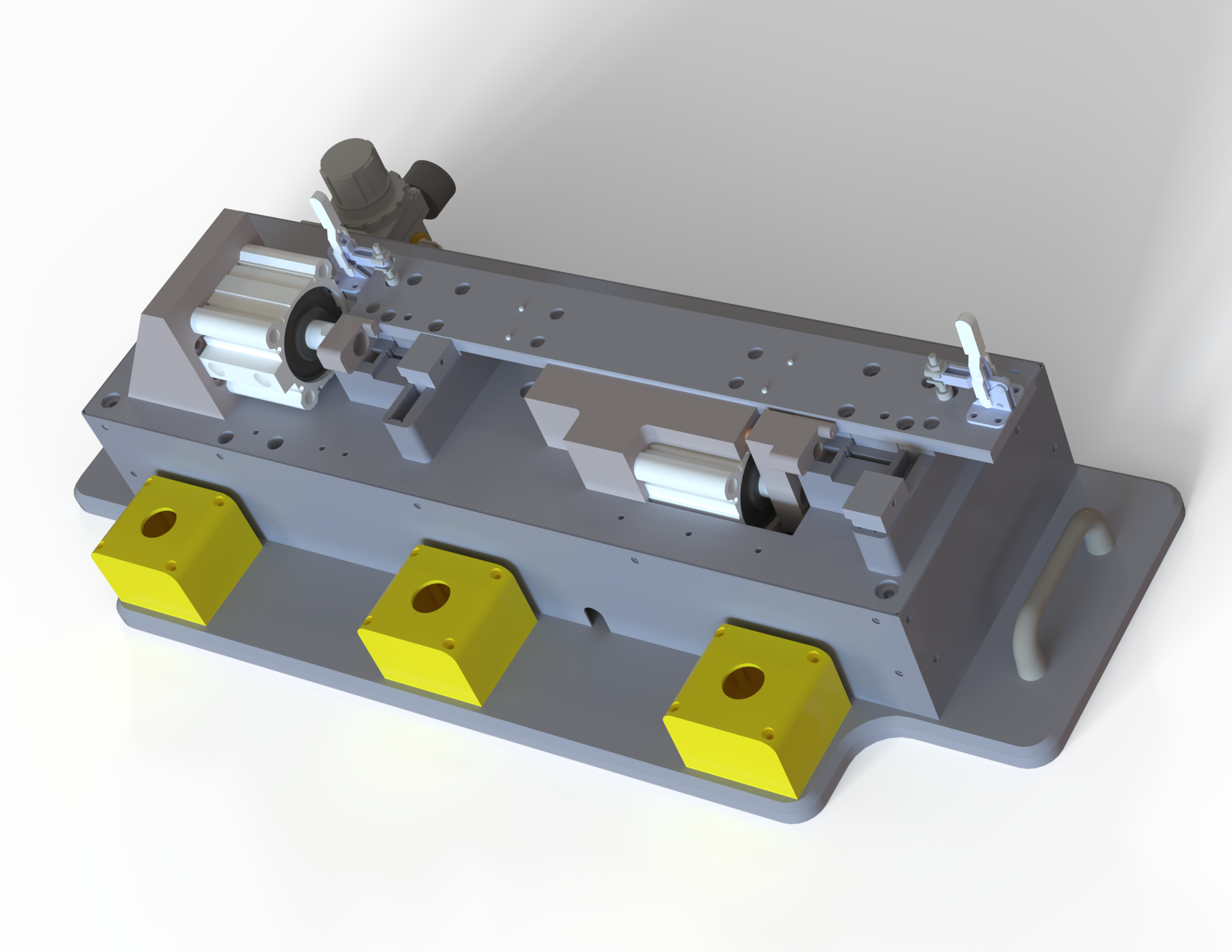

Our precision presses are highly specialized machines designed to apply precise force and controlled conditions to activate adhesives efficiently. Unlike off-the-shelf machinery, these presses are tailored to meet the unique requirements of specific manufacturing processes. Here are some key advantages:

- Enhanced Accuracy: Custom presses ensure consistent force application, eliminating variations that could compromise product quality.

- Scalability: These presses cater to diverse manufacturing scales, from small-scale production to high-volume assembly lines.

- Efficiency Boost: By reducing manual intervention and errors, custom precision presses optimize operational efficiency.

- Versatility: They accommodate various adhesive types, activation methods, and materials, offering unparalleled flexibility.

Key Features of Custom Precision Presses

- Programmable Controls: Advanced automation and programming capabilities enable precise adjustments for each process.

- Temperature Regulation: Built-in heating systems ensure adhesives reach their activation temperature uniformly.

- Force Monitoring: Sensors maintain consistent pressure, ensuring adhesive bonds are strong and reliable.

- Custom Die Design: Interchangeable dies allow manufacturers to adapt to different product specifications effortlessly.

Applications Across Industries

Custom precision presses are transforming adhesive activation in numerous industries:

- Automotive Manufacturing: Securing lightweight panels and structural components with exceptional adhesive bonds.

- Electronics Assembly: Ensuring precision in bonding delicate electronic components.

- Aerospace Engineering: Enhancing the durability and performance of critical aerospace assemblies.

- Medical Device Production: Achieving reliable adhesive activation for high-precision medical equipment.

Innovations Driving the Future

The rise of Industry 4.0 is amplifying the capabilities of custom precision presses. By integrating smart sensors, IoT connectivity, and real-time analytics, manufacturers can monitor and optimize adhesive activation processes like never before. Additionally, advancements in materials science are paving the way for more efficient adhesives that work seamlessly with precision presses, promising a bright future for manufacturing innovation.

Conclusion

Custom precision presses for adhesive activation are revolutionizing the manufacturing landscape. By offering unmatched precision, efficiency, and versatility, they address long-standing challenges and unlock new possibilities across industries. As manufacturers increasingly embrace these specialized machines, they are poised to achieve higher quality standards, faster production cycles, and a competitive edge in a rapidly evolving market.