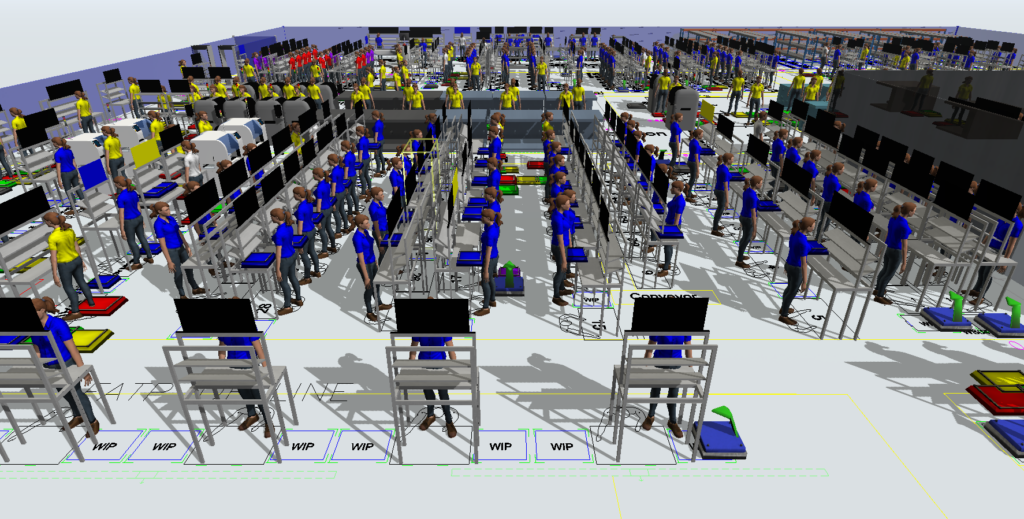

At Custom Industrial Solutions LLC, we specialize in assembly line optimization through cutting-edge simulation techniques. Our goal is to empower manufacturers like you to enhance operational efficiency, tackle flow problems, learn how simulation services improve assembly line efficiency, and eliminate bottlenecks for a more productive assembly line.

What We Offer

- Simulation services assembly line efficiency for Seamless Workflow: Using advanced simulation tools, we model your assembly line to identify inefficiencies and enable data-driven decisions to optimize processes.

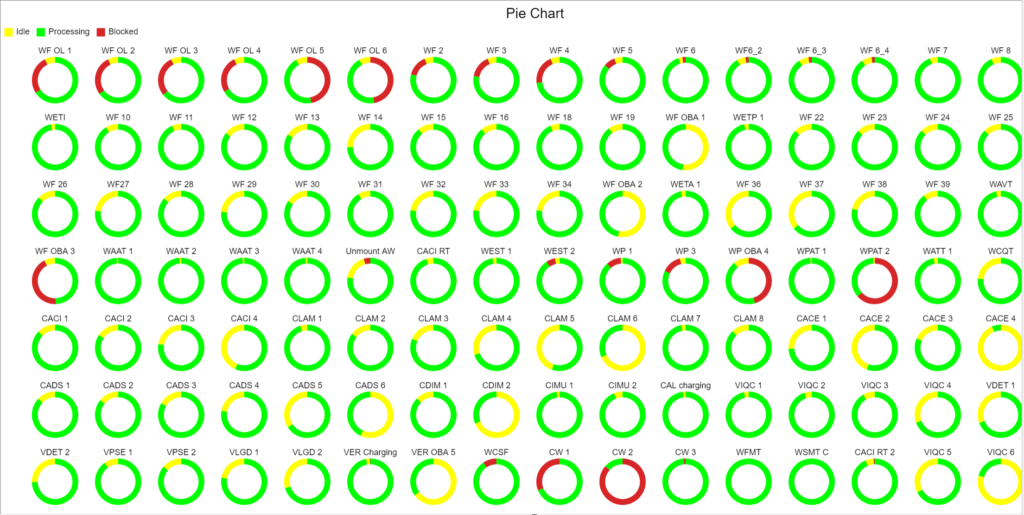

- Bottleneck Analysis: Pinpointing and resolving bottlenecks ensures a smoother, more productive operation, saving you time and resources.

- Utilization Insights: We calculate the utilization rates of workstations and test stations to ensure every part of your assembly line operates at full potential.

Key Benefits of Assembly Line Optimization

Working with us comes with a range of benefits designed to enhance your operations:

- Enhanced Efficiency: Streamline operations and reduce idle time with targeted optimizations.

- Cost Savings: Minimize waste and maximize resource utilization to boost profitability.

- Data-Driven Decision Making: Gain actionable insights to implement changes confidently.

- Flexibility: Adapt your assembly line to meet changing demands without compromising productivity.

- Reduced Downtime: Address bottlenecks effectively to keep operations running smoothly.

Simulation Options

Our assembly line optimization services are customized to meet your unique needs, including:

- Discrete Event Simulation: Analyze workflows and uncover inefficiencies in individual processes.

- Dynamic Simulation: Predict the impact of changes in real-time scenarios.

- Capacity and Utilization Analysis: Evaluate workstation and test station performance to optimize output.

- What-If Scenarios: Explore the potential effects of changes to equipment, layout, or staffing before implementation.

Real-World Examples of Assembly Line Optimization

See how our simulation services have made an impact:

- Automotive Industry: Helped reduce assembly time by 20% through workstation optimization and bottleneck elimination.

- Electronics Manufacturing: Increased production output by 15% by optimizing test station utilization.

- Medical Device Manufacturing: Minimized errors and streamlined production, resulting in faster delivery timelines.

Industries We Serve

We proudly support a wide range of sectors, including:

- Electronics

- Automotive

- Medical Devices

- Packaging

- Consumer Goods

- Mechanical Metal / Sheet Metal Fabrication

Whether you’re working in high-tech industries or producing essential everyday products, we have the expertise to tackle your challenges.

Why Choose Us?

At Custom Industrial Solutions LLC, we stand out for:

- Customized Solutions: Every operation is unique, and our strategies are tailored specifically to your needs.

- Proven Expertise: With years of experience, we have a track record of driving success for manufacturers.

- Collaborative Approach: We work closely with your team to ensure seamless implementation of improvements.

- Cutting-Edge Tools: We leverage the latest simulation technologies to keep you ahead of the curve.

Let’s Transform Your Assembly Line!

Ready to streamline your processes and elevate productivity? Contact us today to learn how our simulation services can revolutionize your assembly line.